Messages: 14

I grew up playing the Ratchet and Clank games on the Playstation so I decided to build one of the weapons from the games.

I'm already in the process of building Clank, so I figured I may as well create Ratchet's OmniWrench as well to go with the display.

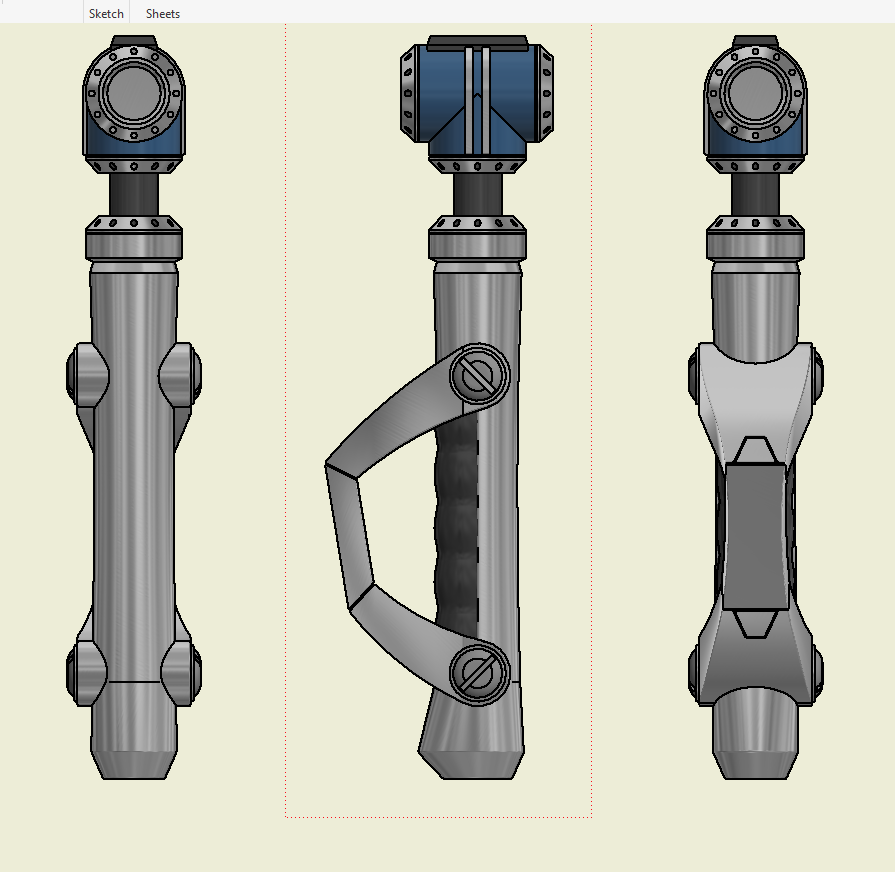

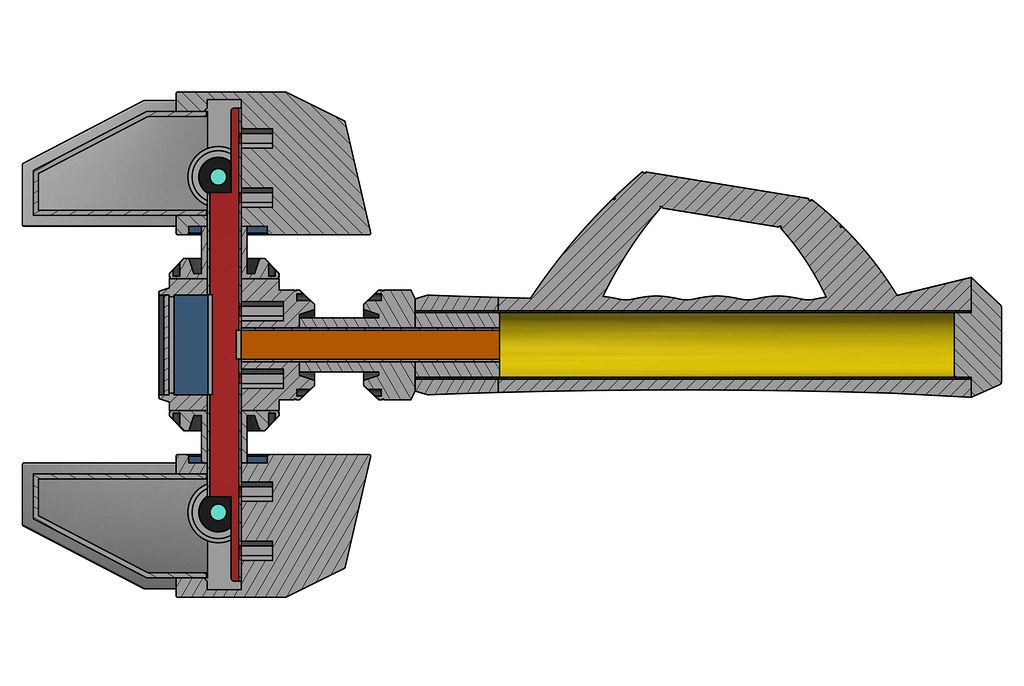

To build my replica I'm using reference photos from the game to create 3D models in Autodesk Inventor.

I first started with modelling the handle and grip section as can be seen below. Since The Ratchet and Clank games are known for oversized fun weapons and gadgets, so I'm scaling my wrench to fit that category. From that, my OmniWrench will total 600mm/23.5 inches in length.

Since it'll be a considerable size, I've designed my files to incorporate metal piping and steel tubing internally. This serves the dual purpose of reinforcing the prop as well as providing me hollow internals that I can run electronics and LED's through.

Here's the work I've completed on the jaws, complete with cavities that I can slot in my LED assemblies

The handle/grip section then transitions into this "central junction" type piece that branches off to each jaw of the wrench, each of which will be connected with steel tubing internally.

April 9th, 2021

And then here's where I'm up to currently with my 3D Model, super pleased with how it's coming along.

April 10th, 2021

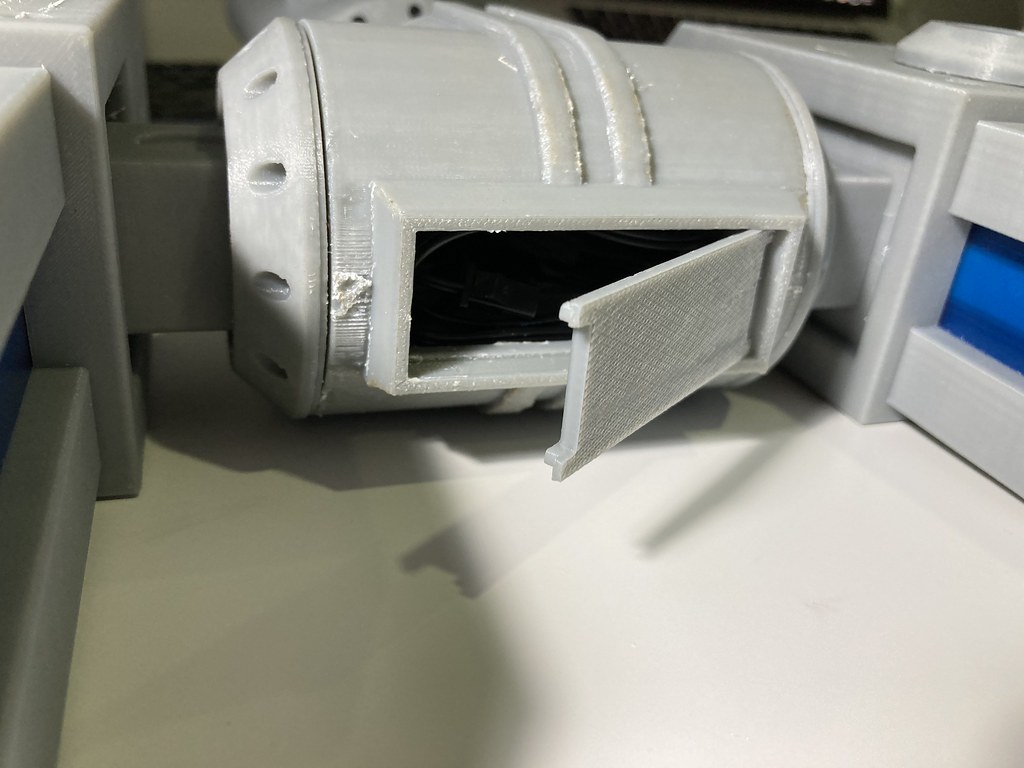

With the exterior modelled, it was time to detail the interior so I could run electronics and wires.

To achieve this I sourced metal pipes/tubing and then modelled the opening to be a really nice tight friction fit.

April 15th, 2021

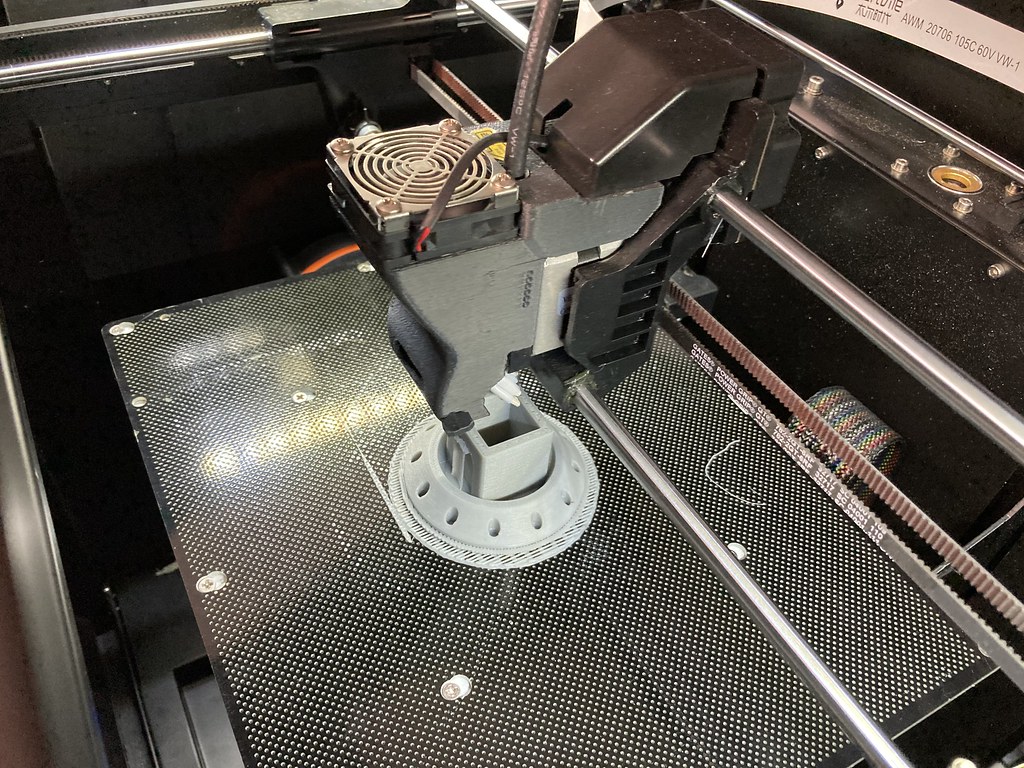

With the 3D model pretty well complete I was able to start 3D printing.

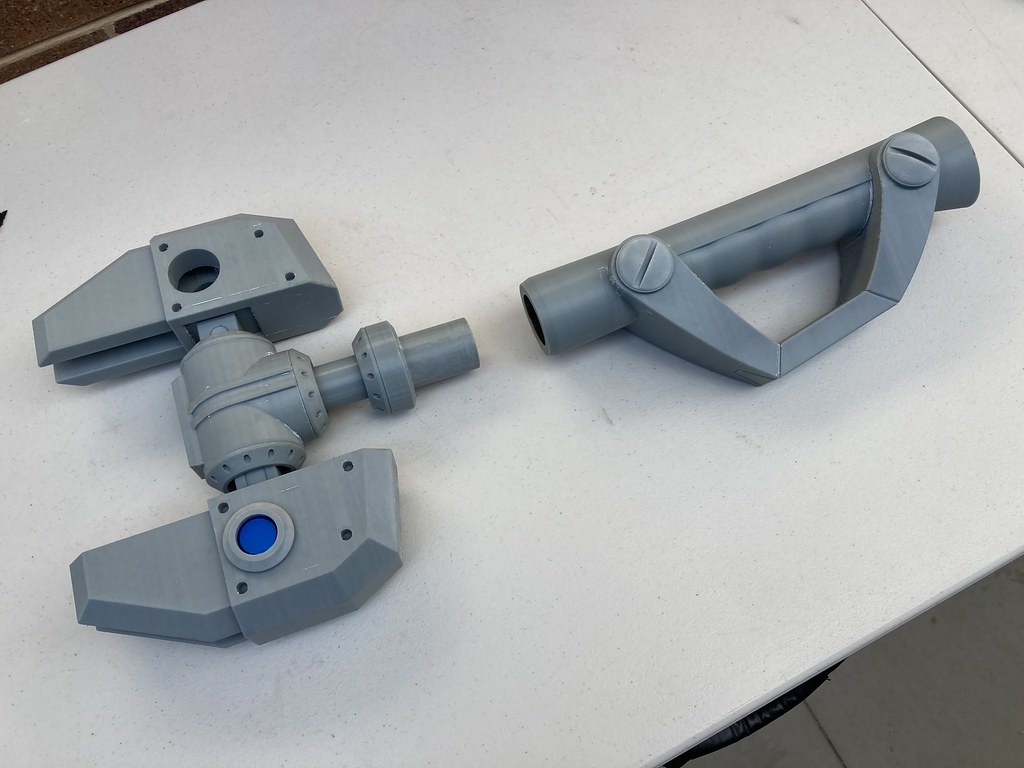

For starters I printed the parts for the central junction area where that connects the handle to the wrench jaws.

I designed this so that the parts were a really snug friction fit over the steel piping. Tight enough that they won't come come off by accident, but I can take parts off for sanding or painting individually prior to final assembly.

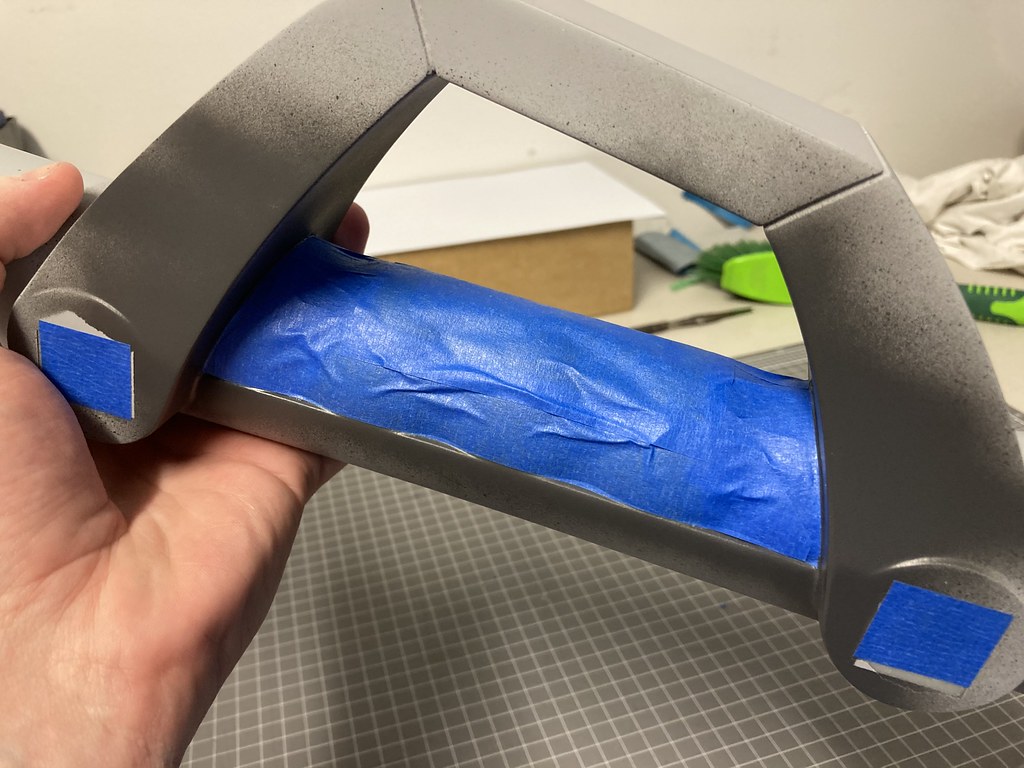

With the top junction area finished it was time to start printing the main handle/grip section. Thankfully I was able to fit this all in one print on my Zortrax M300 3D Printer. Here's some photos of it in progress:

With the handle printed I was able to sleeve it onto the metal pipe I'd be using to house the bulk of the electronics.

I needed to fit a x4 AAA battery holder inside, so I was able to find a metal table leg at Bunnings that was the perfect size for electronics whilst fitting inside the printed parts. This photo was prior to the pipe being cut to length.

April 15th, 2021

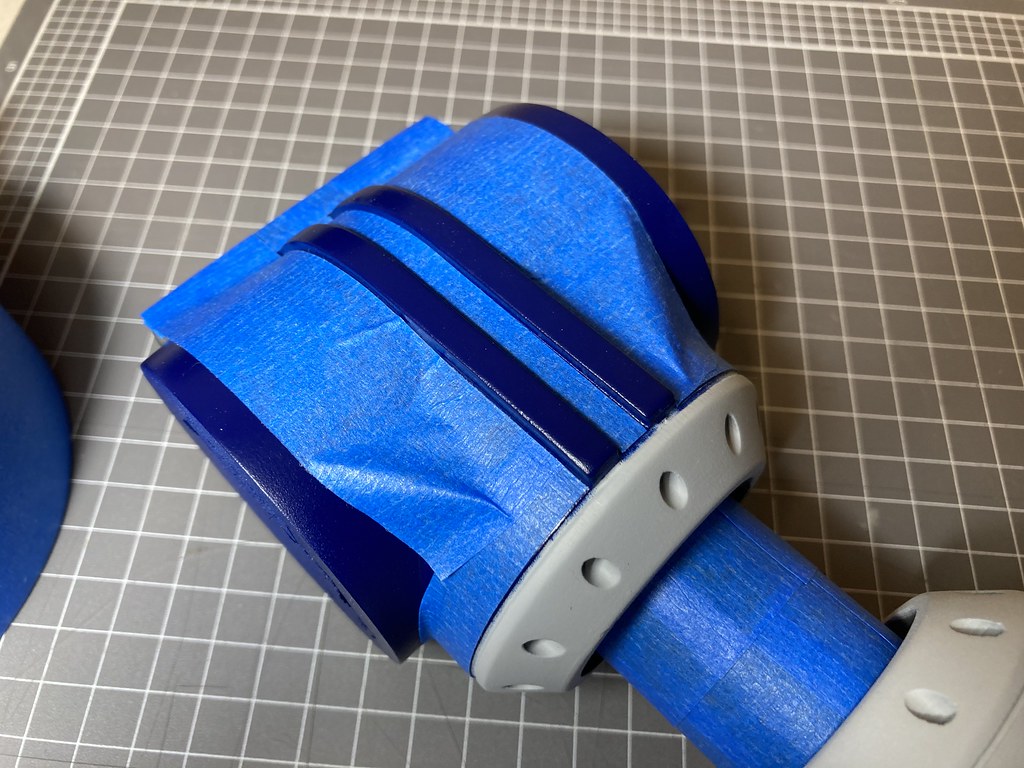

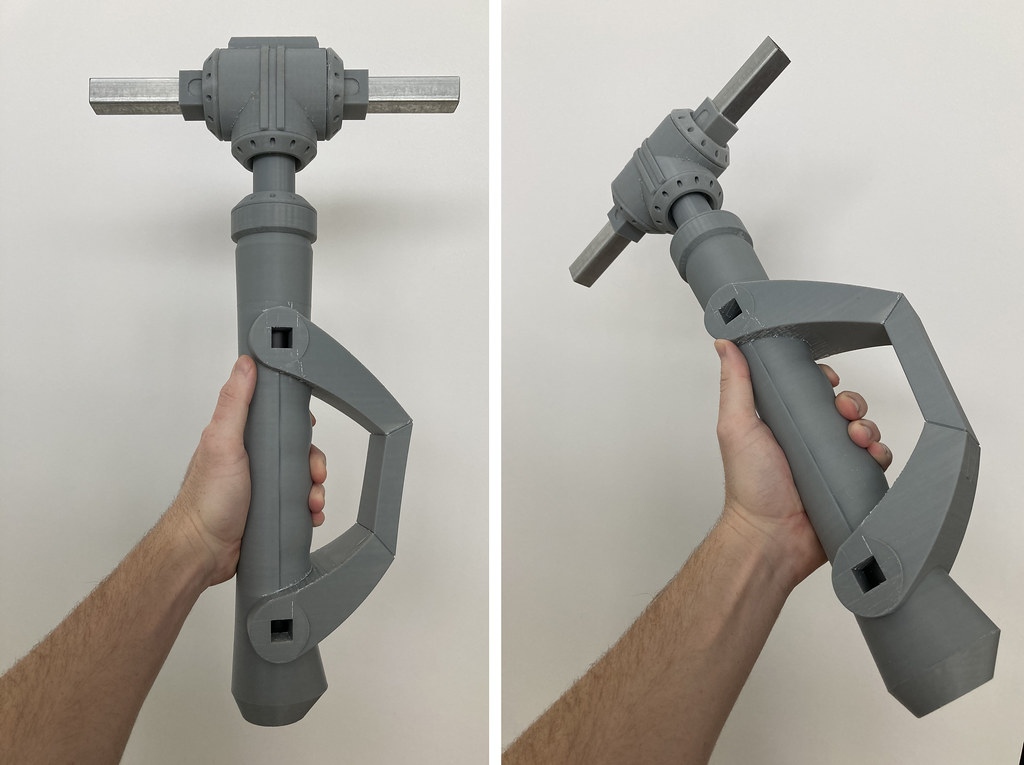

More updates! In the last few days I've printed a bunch more parts. I now have a cap for the pommel and also the jaws of the wrench printed.

Here you can see the junction point for the jaws being fitted to the handle/grip:

Next up, I was able to do a test fit with the first jaw which when really well.

As for the gaps I designed it so that I can drop in a seperate part that contains the light up section.

I also popped in the large decorative flat head bolt caps onto the sides of the handle/grip.

And then here's the wrench with both halves of the jaw fitted! It's really starting to look like the real deal now

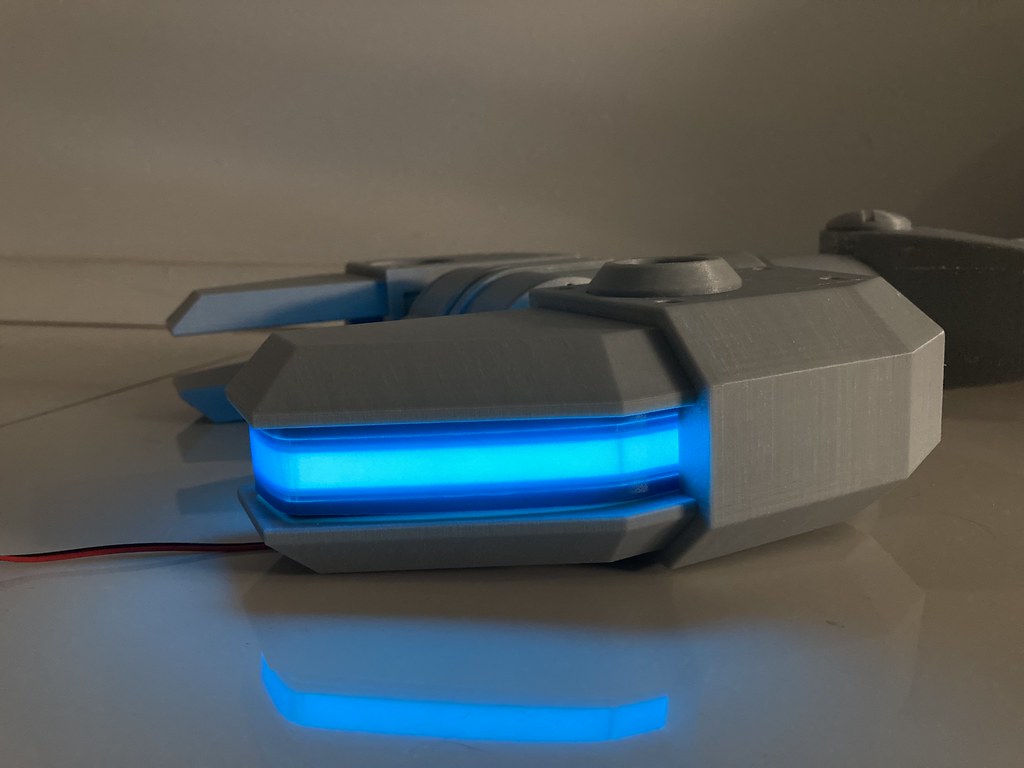

You can also see one of the light panels for the blue LED's. For the lens I used an transparent blue arcade button to get the look I was after.

April 17th, 2021

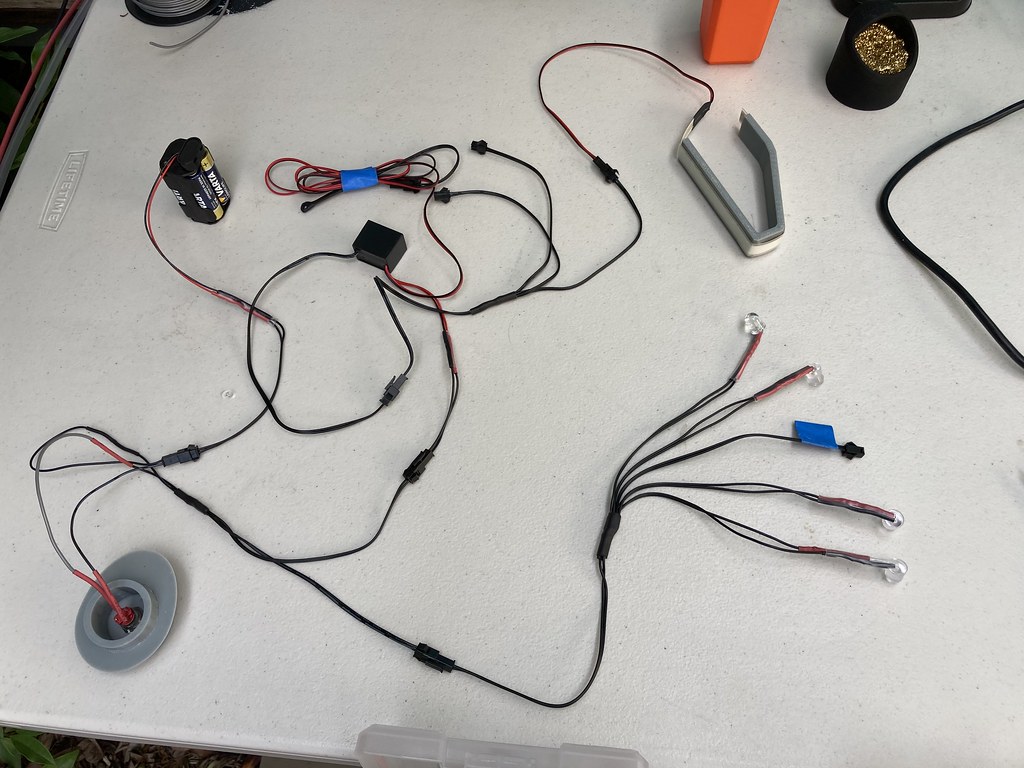

With nearly the entire wrench printed I was able to begin developing a prototype solution to lighting the jaws of the wrench.

Initially I was looking at LED strips, however the uneven distribution of the lighting would leave a lot to be desire for me.

So after some reach into alternatives, I settled on Electroluminescent Tape. The Electroluminescent Tape is great since it provides a nice consistent lighting source. It's really nice and flexible and I can bend it even up to 90 degrees, the only down side is it isn't as bright as LED strips.

This is the strip as it arrived:

To mount it the LED strip in the jaw area I printed a thin profile that's a nice friction fit. I then used strong double sided tape attach the Electroluminescent tape.

Here's how it looked in position within the jaw:

With the tape mounted I needed to make an addition 'lens' to further add to the look.

My low tech solution was to go to the local office supply shop and purchase an opaque blue plastic folder.

I then chopped some strips on a guillotine. Once cut, I got my heat gun and heated a section at a time and then bent it to shape.

Then the moment of truth! The first test with lighting it up!

Super stoked with how this is looking

April 18th, 2021

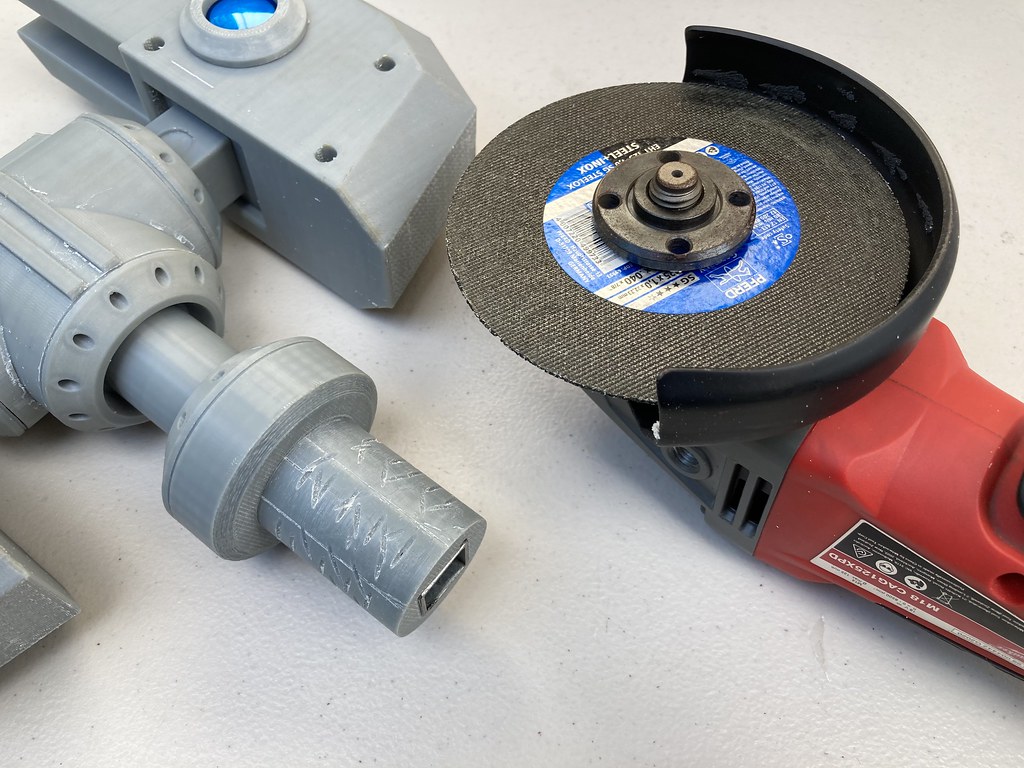

With the Electronics prototype sorted I needed to make the steel piece that connected the two jaws to the handle.

To achieve this I used the square steel tube I cut from earlier. Next I marked out which sections I needed to cut with the angle grinder.

After the cutting with the grinder was complete, this was how the steel was looking.

The sections I had removed allow for my to run the electronics inside without obstruction.

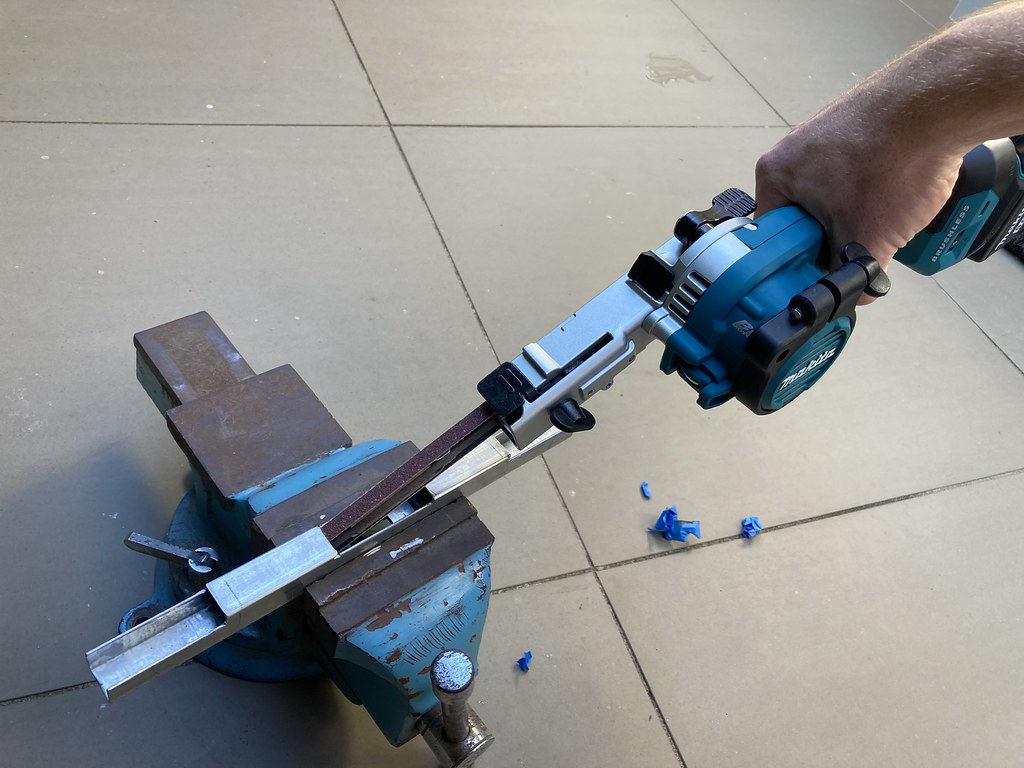

With the cutting complete I used my power file to quickly remove all the burrs and removing flashing so that the wiring wouldn't snag on anything.

After a once over with the power file, this is the result:

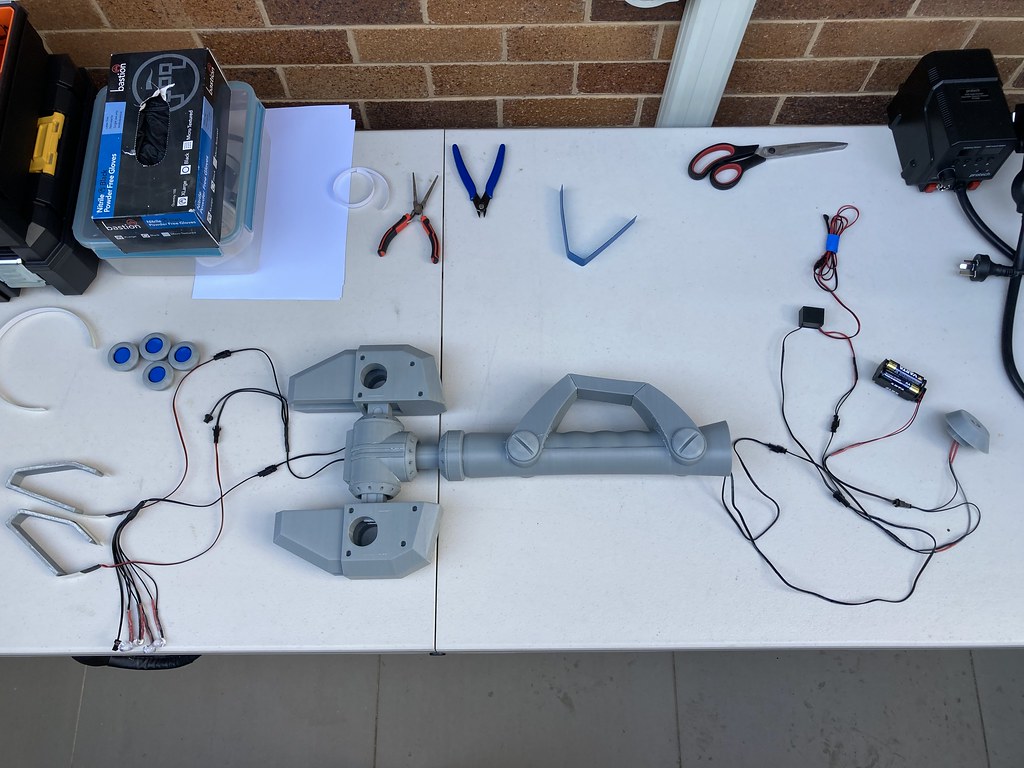

With the steel piece completed it was time to prep the jaws with threaded inserts.

Essentially what will happen is I will have holes in the steel that I just made that line up with threaded inserts in the jaws. Then when I sleeve the jaw onto the steel I can thread a bolt through securing the two parts together. This allows for a rock solid assembly that I can still disassembly If I need for working on electronics or painting.

When I 3D modelled the jaws I allowed for a while that I could fit some M6 coupling cuts into. The tolerances were designed such that I needed to hammer them into the hole. There's no way they're going anywhere! I also measure to bump up the infill on the 3D print to make sure that nothing buckled when hammering.

Here's the coupling nuts:

And then here's the coupling nut installed into the hole:

With the coupling nuts installed I was able to drill the corresponding holes in the steel. Here's how it looks with the jaws bolted in place to the steel and the handle:

This week I plan to get the electronics all soldered up properly and installed, so I'll have more photos to come soon!